Scratch building a Non Corridor 3rd Diag. C83 (Contd.)

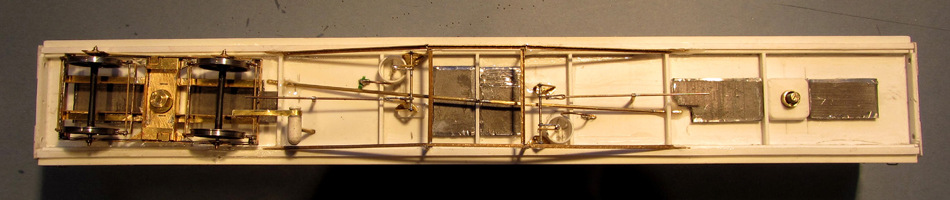

Underframe

The underframing consists primarily of trussing, brake gear, steam heating pipes, battery boxes, dynamos, steps, etc. Most of these are illustrated above. Before starting on any of them, I put in some cross braces from plasticard and added some lead weight secured with epoxy. The two sets of trussing were made up from 1mm brass angle. After cutting to length and with ends filed to shape, the components were pinned to a pattern marked on mounting card and soldered together. With the two frames held in place with bluetack, the cross members were soldered in place. The whole assembly was then fixed in place with epoxy.The brake gear is made up from Masokits Mk1 parts and brass wire using photographs as a guide. The vacuum cylinders are short lengths of plastic tube! The steam heating pipe is brass rod with hangers cut from brass shim. The battery boxes (see below) are from the Frogmore Confederacy range from Dart Castings. The dynamo is made up from plastic tube and Milliput filler with a hanger from brass rod.

The steps also came from the Frogmore Confederacy range. These were folded up and soldered to brass wire hangers. These were threaded into holes in the floor and secored with epoxy.

The steps also came from the Frogmore Confederacy range. These were folded up and soldered to brass wire hangers. These were threaded into holes in the floor and secored with epoxy.

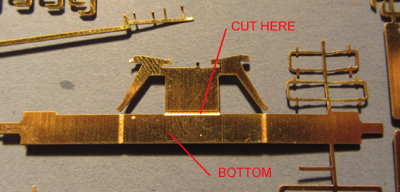

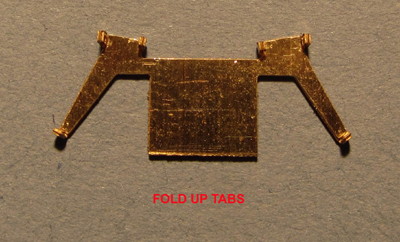

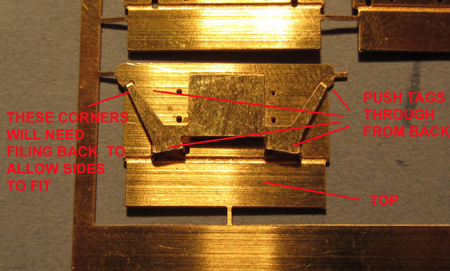

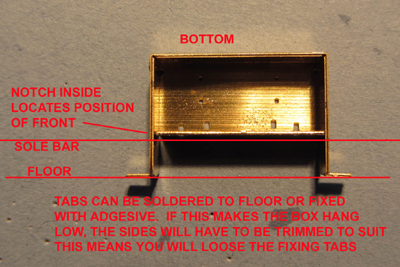

Battery Boxes

A while back, I received a request for help in assembling these etches and produced some photographic guides which were published on RM Web. These are repeated below.

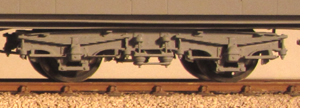

Bogies

The sprung bogies are from Bill Bedford. He doesn't list a GWR 9'0" bogie but, as they are only functional, I ordered LMS versions. This was assembled as per the instructions, incorporating the raised bolster which needed opening out to accomodate the tube pivot mounted on the coach body. I used Alan Gibson waisted pinpoint bearings as these seem to work well with the Exactoscale axles, without the need for the washers recommended in the instructions. Wheels were, needless to say, also from Exactoscale. I had a spot of bother getting the brake shoes to clear the wheels but got there in the end. The white metal GWR 9'0" Pressed Steel cosmetic sides are from the MJT range from Dart Castings. These needed a little tidying up, some material was removed from the back and the recesses for the bearings were opened up a little. Not too much or you will break out through the axle box! The steps were scratch built in brass and soldered to the sides with low melt solder, not the easiest of jobs.

The sprung bogies are from Bill Bedford. He doesn't list a GWR 9'0" bogie but, as they are only functional, I ordered LMS versions. This was assembled as per the instructions, incorporating the raised bolster which needed opening out to accomodate the tube pivot mounted on the coach body. I used Alan Gibson waisted pinpoint bearings as these seem to work well with the Exactoscale axles, without the need for the washers recommended in the instructions. Wheels were, needless to say, also from Exactoscale. I had a spot of bother getting the brake shoes to clear the wheels but got there in the end. The white metal GWR 9'0" Pressed Steel cosmetic sides are from the MJT range from Dart Castings. These needed a little tidying up, some material was removed from the back and the recesses for the bearings were opened up a little. Not too much or you will break out through the axle box! The steps were scratch built in brass and soldered to the sides with low melt solder, not the easiest of jobs.

Buffers and pipework

Sprung buffers came out of my stock box. Vacuum and steam heating pipes were scatch built from wire.

Seats

The seats came from Comet in strips and were cut to length to suit. They needed a little packing to get the correct height and angle and were painted prior to fixing.

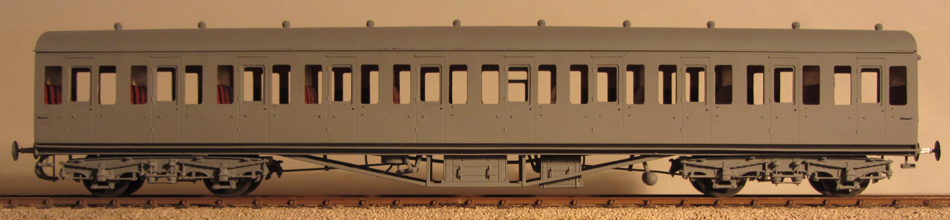

Painting, glazing and final detailing

Everything was given a light coat of grey primer. The inside was handpainted before fitting the seats. Thin card was cut to fit into the glazing apertures prior to spraying the body with Precision Paints BR Crimson. A relatively thin coat of this over the grey primer gives a good representation of BR Maroon to suit the period being modelled. The roof was sprayed from a Railmatch Roof Dirt aerosol can. The bogies were hand painted with a mix of Railmatch Frame and Roof Dirt.

0.33mm clear plastic sheet was cut to size and slotted into the recessed apertures in the body sides. The glazing is a snug fit and is retained by the roof.

Lettering is HMRS Pressfix.

Door handles came from Blacksmith Models and were filed down to the correct size and shape. Grab handles were bent up from brass wire in one of Bill Beford's great little jigs.